Any intermediate sheets are coated with clay on top and dye on the bottom (Coated Front and Back, CFB).

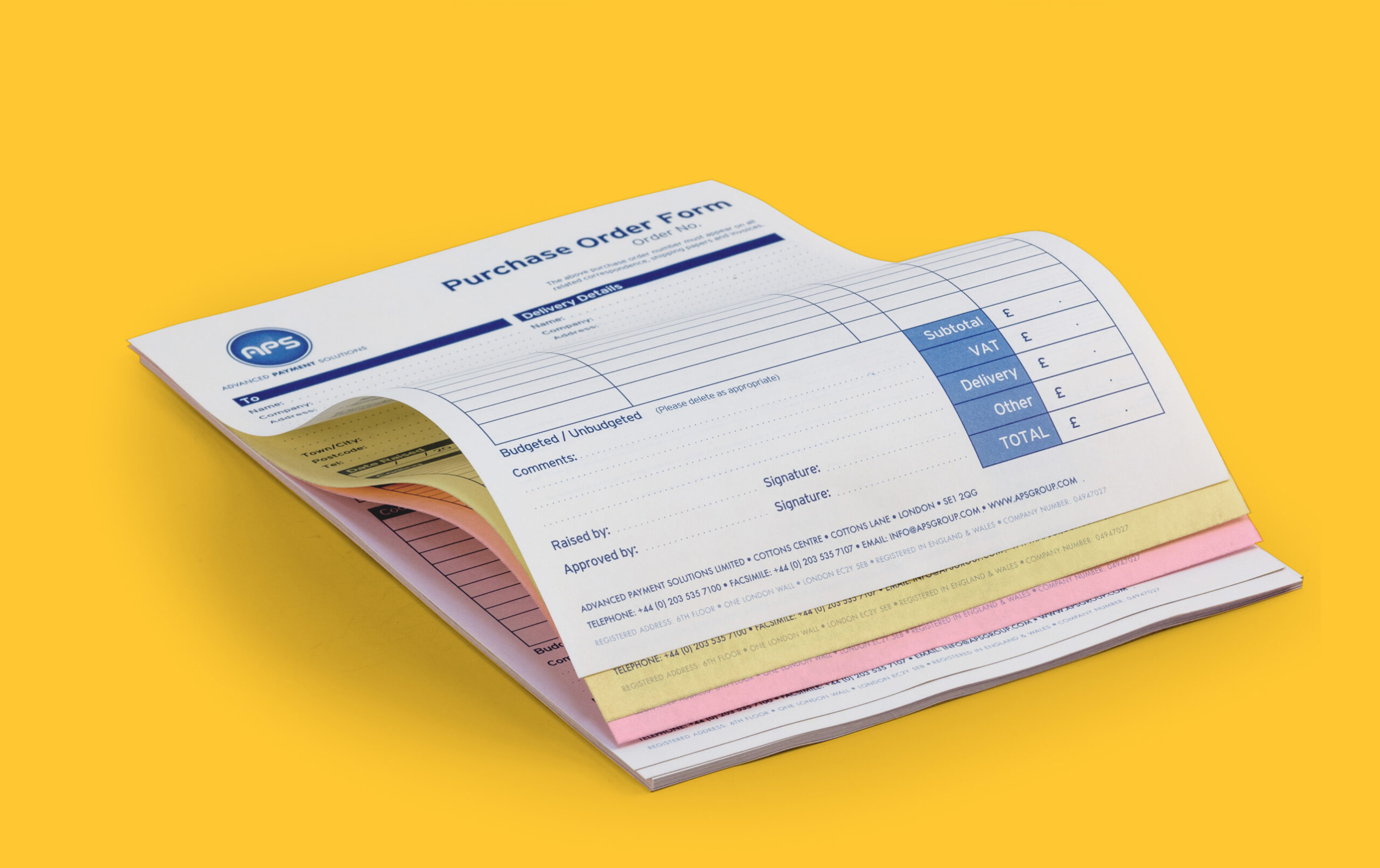

The lowermost sheet is coated on the top surface with a clay that quickly reacts with the dye to form a permanent mark (Coated Front, CF). The back of the first sheet is coated with micro-encapsulated dye (referred to as a Coated Back or CB sheet). Intermediary sheets, with clay on the front and dye capsules on the back, can be used to create multiple copies this may be referred to as multipart stationery.Ĭarbonless copy paper consists of sheets of paper that are coated with micro-encapsulated dye or ink or a reactive clay. When pressure is applied (from writing or impact printing), the dye capsules rupture and react with the clay to duplicate the markings made to the top sheet. Carbonless copy paper has micro-encapsulated dye or ink on the back side of the top sheet, and a clay coating on the front side of the bottom sheet. It was developed by chemists Lowell Schleicher and Barry Green, as an alternative to carbon paper and is sometimes misidentified as such.Ĭarbonless copying provides an alternative to the use of carbon copying.

Carbonless copy paper ( CCP), non-carbon copy paper, or NCR paper (No Carbon Required, taken from the initials of its creator, National Cash Register) is a type of coated paper designed to transfer information written on the front onto sheets beneath.

0 kommentar(er)

0 kommentar(er)